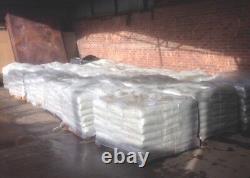

1000KG Of Glass Sand Blasting Media Fine Grade Grit For Blast Guns Or Cabinets

NEW MASSIVE PALLET 1 TON 40 x 25 KG HEAVY DUTY SACK OF GLASS SAND BLASTING GRIT 0.2 to 0.8 GRADE GLASS MEDIA FOR SODABLAST REPLACEMENT SAND BLASTING / FINISHING / DESCALE. Glass media can provide company's of all sizes with a cost effective and environmental solution compared to traditional abrasive media. Our glass media is manufactured to, and in accordance with, BSI PAS102 and under ISO 9001 quality control systems. These accreditations mean we can guarantee constant quality time and time again.

Reduced Costs and Reduce Blast Time with our High Performance Glass Abrasives. This Glass media performs as well, if not better in some cases than conventional shot blast abrasives Glass particles are angular to sub-angular and have the ability to cut coatings exceptionally well when used in abrasive blasting Glass media's produce a "white metal" finish which can be superior to other abrasives Glass media can be used in volatile areas such as gas pipe lines /petrol tanks etc, as there is no'cold sparking' Low "rust-back" finishes can be produced by using glass unlike other abrasives, glass does not contain significant chlorides or other salts which can accelerate the corrosion of cleaned surfaces Using glass can have the potential for much lower dust generation compared to other abrasives during use. Not only does this have many H&S benefits, it can also reduce the number of complaints received Glass is also free from silicates and heavy metals meaning it is a safe product for the user with less dangerous dust generation, glass can leave less abrasive residues on cleaned surfaces thereby reducing post-blast cleanup costs and time Unlike many conventional blast abrasives like copper slag, glass is classed as an inert and nonhazardous waste, this can significantly reduce your disposal costs. Glass is non-toxic and inert, unlike copper and other metal derived abrasives that contain heavy metal residues. Heavy metals can be harmful to the environment (& the user), particularly plant and marine life.

Glass can be used when working in and around environmentally sensitive areas such as watercourses, marina's etc as the media is completely inert and will pose no environmental risks should spillage occur. Disposal of "spent" glass media will have fewer negative environmental impacts than slag-based abrasives as glass is not classed as hazardous waste - Unlike slag-based abrasives, glass contains no heavy metals which can potentially increase potential environmental contamination Glass grit abrasives can also be reused more than some other lower cost abrasives before becoming "spent", therefore having environmental benefits as well as financial ones Using glass abrasives utilises glass cullet sourced from local container glass waste streams and creates a resource from a material that would otherwise be committed to landfill.This can significantly reduce a company's carbon foot print and demonstrates a proactive attitude to reducing waste and protecting the environment Currently there is a surplus of mixed glass cullet due to an imbalance between production and collection. Using recycled glass for shot blasting provides the opportunity to correct this imbalance and saves it going to landfill.

Unlike many other mineral based abrasives, glass has no detectable "free" or "crystalline" silica, greatly reducing the potential health hazards for user which eliminates users from silicosis, a lung damaging disease which can be fatal Glass has the potential for lower dust generation than some other abrasives during use, this can be safer to use in public areas. It can also help decrease the amount of complaints received Unlike slag-based abrasives, glass grit contains essentially no heavy metals which can potentially increase occupational exposure during use recycled glass is a clean and safe to handle material. All of our glass grit is completely non-sharp and can be handled without the risk of cutting to the user. However as with all shot blasting abrasives PPE should always be worn.

SEE OUR POSITIVE FEED BACK FROM OUR CUSTOMERS. > PLEASE CONTACT BEFORE ORDERING TO DISCUSS DETAILS, FREE COLLECTION AVAILABLE. This item is in the category "Business, Office & Industrial\Cleaning & Janitorial Supplies\Other Cleaning Supplies". The seller is "unitedabrasivesltd" and is located in this country: GB.This item can be shipped to United Kingdom.

- Modified Item: No

- Country/Region of Manufacture: United Kingdom

- Unit Quantity: 1000

- Unit Type: kg

- Brand: UNITED ABRASIVES LTD